In today's construction and landscaping markets, the use of Polyethylene Drainage Pipe is becoming essential. According to a recent report by the International Pipe Association, the demand for drainage solutions has surged by 25% over the last five years. This rise is largely due to increasing awareness of sustainable practices and efficient water management systems.

Renowned expert Dr. Emily Carter, a leading voice in the drainage materials industry, states, "Choosing the right drainage solution can significantly impact infrastructure longevity." Her words underscore the importance of selecting appropriate materials for various applications. Polyethylene Drainage Pipes offer flexibility and durability, making them ideal for both residential and commercial projects.

Yet, challenges remain. Some users have reported installation difficulties, causing potential setbacks. Reflecting on these experiences is crucial to enhance future practices. While Polyethylene Drainage Pipes provide many benefits, there remains a need for continuous improvement in user education and installation techniques. Understanding these factors will ensure better usage and maximize their advantages in drainage systems.

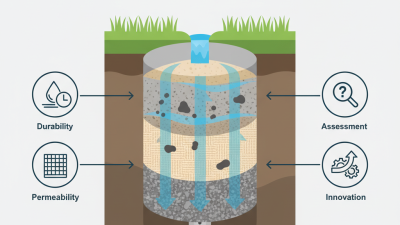

Polyethylene drainage pipes have become a popular choice in various applications. They are known for their durability and flexibility. According to the Plastics Pipe Institute, over 90% of drainage systems utilize polyethylene due to its resistance to corrosion. This makes it ideal for a range of environments, from agricultural to urban settings.

One key benefit is their ability to handle large volumes of water. The flow capacity of these pipes often exceeds that of traditional materials, significantly reducing the risk of clogs. However, there are concerns about installation. Improper backfilling can lead to deformation or leaks. A recent study indicated that nearly 25% of field installations failed to meet quality standards.

Moreover, while polyethylene pipes are generally lightweight, this can be a double-edged sword. They require careful handling to avoid damage during transport. It's also important to consider environmental factors. Some regions may see accelerated wear due to UV exposure, which can shorten the lifespan of the pipe. Understanding these nuances is vital for making informed decisions in drainage solutions.

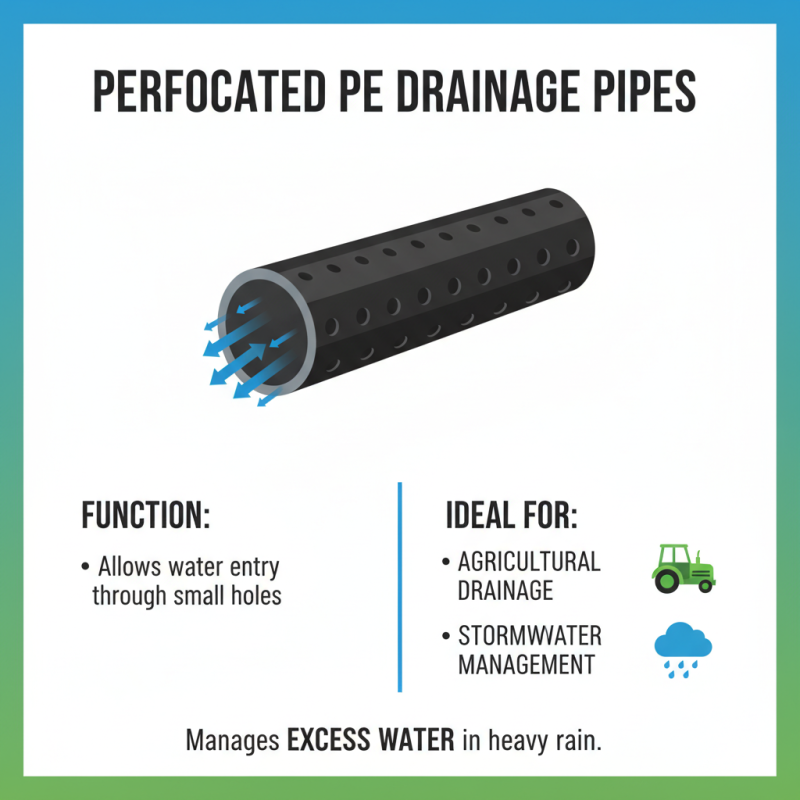

When choosing polyethylene drainage pipes, it's essential to understand the different types available. There are perforated pipes, which are designed to allow water to flow through small holes along the length. These pipes are ideal for applications like agricultural drainage and stormwater management. Their ability to transport excess water makes them vital in areas with heavy rainfall.

Non-perforated pipes are another option. They direct water flow without allowing it to seep through. These pipes often serve as main drainage lines, efficiently transporting water away from structures. They can be combined with perforated pipes for effective drainage systems. However, it's worth noting that improper installation can lead to drainage failure.

Additionally, corrugated polyethylene pipes offer flexibility and durability for various applications. They are lightweight, making transportation easier. Yet, their thin walls can be prone to damage in harsh conditions. Always consider the specific needs of your project when selecting a type. Testing different configurations may lead to unforeseen issues that require further adjustments and reflections on efficiency.

When selecting drainage pipe solutions, several factors come into play. The type of polyethylene pipe is essential. Consider your project's specific needs, such as load-bearing capacity and soil conditions. A flexible pipe might work well in uneven terrain, while a rigid pipe could suit flat landscapes better.

Tip: Always assess the local climate. Extreme weather can impact drainage. In areas with heavy rainfall, larger pipe diameters may be necessary. For drier climates, a smaller pipe could suffice. Look into the pipe's durability as well. A pipe that withstands harsh conditions is crucial for long-term performance.

It’s worth reflecting on installation practices. Improper installation can lead to significant issues. Accumulating debris can block your pipes if not correctly sloped. Make sure to plan for maintenance access. Lack of foresight can complicate repairs down the road. Ultimately, a thoughtful approach to these factors can enhance your drainage system's efficiency.

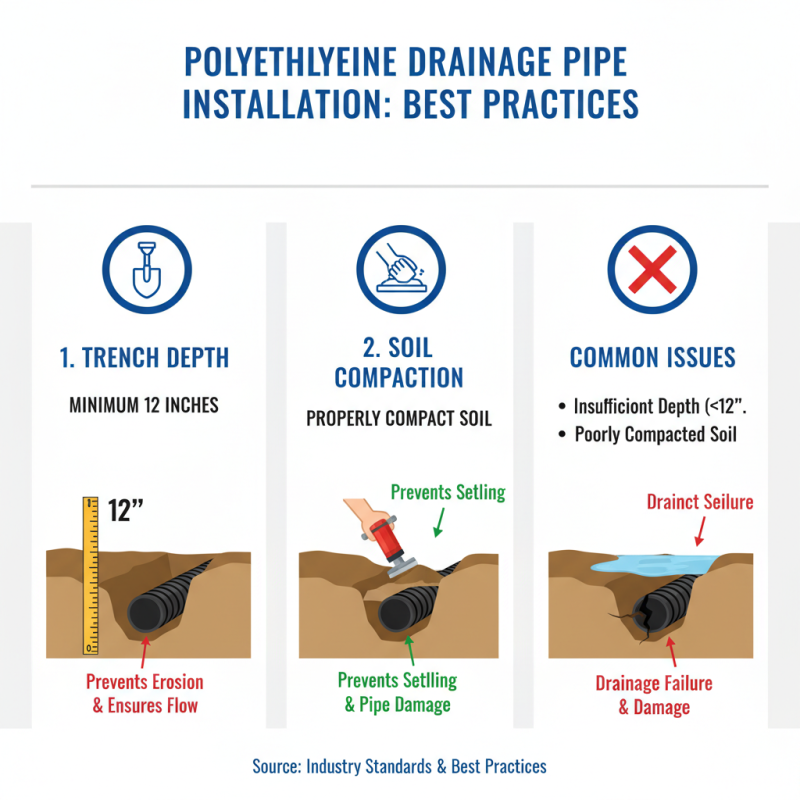

Installing polyethylene drainage pipes can seem straightforward, but it requires careful attention to best practices. Proper trench depth is crucial. According to industry standards, trenches should be at least 12 inches deep for effective drainage. However, many installations fail to meet this depth, leading to insufficient drainage and erosion. A common issue arises from poorly compacted soil. This can cause settling and eventual pipe damage.

Choosing the right fittings is equally important. Using incompatible materials can lead to leaks. For example, the use of PVC connectors with polyethylene pipes often fails under stress. Regular inspections during installation can catch these errors. Experts recommend checking joints regularly; a staggering 30% of drainage issues stem from improper fittings.

Finally, backfilling should be done with care. Using large rocks can puncture the pipe. Smooth materials provide better protection. However, many times, installers overlook this detail. They may assume that any soil will suffice. This can lead to serious long-term issues. Ensuring that these best practices are followed can greatly enhance the longevity and effectiveness of polyethylene drainage systems.

Maintaining a polyethylene drainage system is crucial for its longevity. Regular inspections can help catch problems early. Look for signs of wear, such as cracks or blockages. Clearing debris from inlets can prevent buildup.

One of the best maintenance tips is to flush your pipes regularly. This simple step keeps water flowing smoothly. Use a garden hose for light cleaning. For tougher clogs, consider a plumber's snake. Avoid harsh chemicals that could damage your pipes.

It's also wise to monitor water flow. Slow drainage can indicate a larger issue. If you notice unusual sounds, it's time to investigate further. Neglecting small issues can lead to costly repairs. Maintain a checklist for your drainage system, and stay proactive.