The Flexible Soft Permeable Pipe is an innovative solution for various applications. It allows for efficient water management and drainage in a variety of environments. This type of pipe is designed to adapt to different conditions, ensuring optimal performance.

Made from advanced materials, the Flexible Soft Permeable Pipe promotes sustainability. It enables proper filtration and prevents waterlogging in agricultural fields or urban landscapes. The permeability of this pipe enhances soil health and supports plant growth.

Users often appreciate its versatility. However, there may be challenges in installation and maintenance. Understanding the specific needs of each project is crucial. The importance of proper handling cannot be overlooked. This ensures that the pipe functions effectively over time. Embracing the benefits while acknowledging the complexities is essential for success.

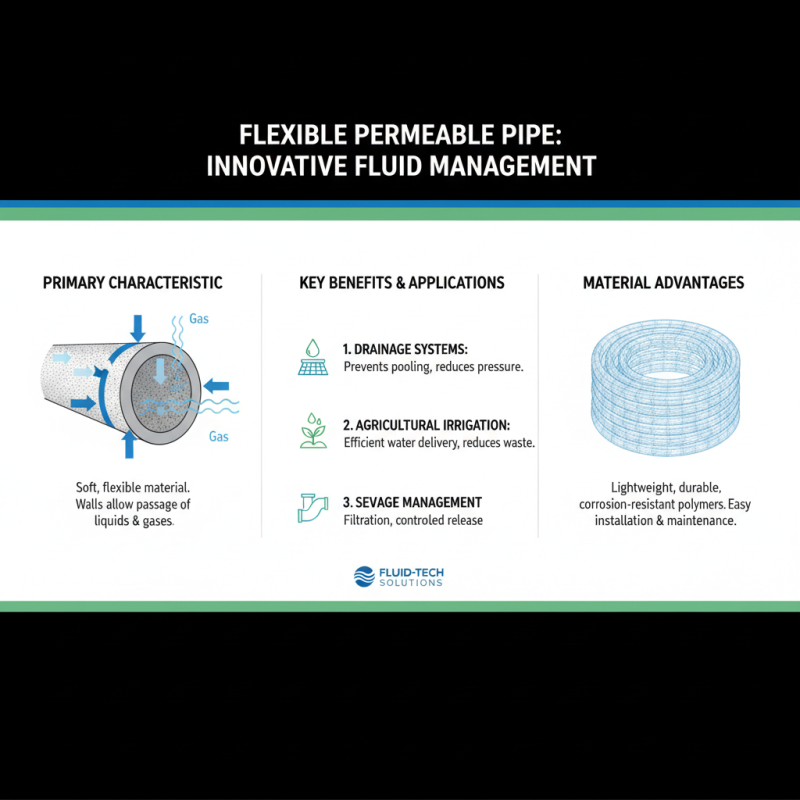

A flexible soft permeable pipe is designed for various practical applications. Its primary characteristic is the ability to allow liquids and gases to pass through its walls. This feature helps in drainage systems, agricultural irrigation, and sewage management. The materials used are typically lightweight and durable, which makes installation easier.

One of the key characteristics of these pipes is their flexibility. They can bend and conform to different shapes and terrains. This adaptability is crucial in uneven landscapes, helping to prevent damage. Additionally, the surface texture influences permeability. A rough surface can enhance water flow, but it can also lead to blockages over time.

Users should consider the right application carefully. While these pipes are effective, they can wear out and require replacement sooner in harsh environments. Understanding the limitations and maintenance needs is essential. In some cases, improper installation might lead to issues that could require costly repairs. Balancing benefits with potential drawbacks is vital for long-term success.

Flexible soft permeable pipes are becoming popular in various industries. The composition of these pipes is crucial for their effectiveness. Typically, they are made from advanced polymer materials. Polyethylene and rubber are common choices. These materials offer flexibility and durability. A report by the Global Pipes Association indicates that the demand for such pipes increased by 15% in the past year.

The manufacturing process involves several steps. First, raw materials are blended carefully to achieve desired properties. This process requires precision. Next, the mixture is extruded into the desired shapes. Adjustable molds help create custom designs. Surprisingly, many manufacturers still face challenges in quality control. Consistency can vary, leading to performance issues in the final product.

Post-production, these pipes undergo multiple tests. Pressure and durability tests are crucial. Despite advances, some pipes still fail to meet industry standards. A notable 25% of companies reported issues related to permeability. This highlights the importance of constant innovation in material science to enhance product reliability. Understanding these factors can guide better usage in practical applications.

Flexible soft permeable pipes are increasingly popular in water management, especially in agriculture and environmental applications. These pipes allow water to flow through their walls, offering benefits in irrigation and drainage systems. In agriculture, they help prevent waterlogging. Farmers can direct water to where it is needed, optimizing crop yield.

In environmental projects, these pipes support sustainable practices. They help manage stormwater effectively and reduce pollution runoff. By allowing soil to breathe, they promote healthier ecosystems. Conservation efforts also benefit from their use. However, improper installation may lead to leaks or inefficiencies. Consider the local environment before choosing a pipe type.

Tip: Always assess soil conditions. Different soils interact differently with water.

Understanding the flow rates is crucial, too. Overestimating can waste water, while underestimating can harm crops.

Tip: Test water infiltration rates for your specific site. This knowledge will guide your decisions. Take time to learn from your initial installations. Adjust and refine your approach based on previous experiences.

Flexible soft permeable pipes are increasingly favored in various industries. They offer unique advantages, especially concerning performance metrics. The durability of these pipes is one of their standout features. According to industry reports, high-quality flexible pipes can endure pressures up to 200 psi, demonstrating impressive resistance to physical stress.

Flexibility plays a crucial role in the application of these pipes. Their ability to bend and contour helps in navigating complex terrains and tight spaces. This adaptability is particularly beneficial in agricultural settings, where uneven ground can present challenges. The American Society for Testing and Materials (ASTM) outlines that optimal flexibility is essential for maintaining structural integrity under varying temperatures.

Permeability standards, too, deserve attention. Research indicates that permeable pipes can manage water flow efficiently, reducing the risk of waterlogging. However, the quality of materials used significantly affects performance. Inconsistent manufacturing processes can lead to variations in permeability. This inconsistency sometimes results in unexpected failures, underscoring the importance of rigorous quality control. Each project should thoroughly evaluate these metrics to ensure satisfactory outcomes.

The flexible soft permeable pipe technology is increasingly gaining traction in various industries, primarily due to its innovative applications. According to a recent market report, the demand for permeable pipe systems is projected to grow by approximately 7% annually over the next five years. This growth is driven by rising environmental concerns and the need for sustainable practices in construction and agriculture.

Current trends highlight the integration of smart technologies with soft permeable pipes. Sensors embedded within the pipes can monitor water flow and detect leaks in real-time. This innovation enhances efficiency and reduces waste significantly. However, some challenges remain. These technologies can be costly, and not every application justifies the expense. Additionally, the installation processes can be complex, requiring skilled labor.

Research indicates that improving the durability of materials used in these pipes is essential. Many existing products face issues like degradation from UV exposure and environmental factors. As manufacturers adapt, there is a need for continuous improvement and testing to ensure longevity. The industry is at a crossroads where innovation is necessary, yet practical limitations persist. Exploring these factors could redefine how soft permeable pipes are used.

| Dimension | Description | Applications | Future Innovations |

|---|---|---|---|

| Material | Flexible polyolefin or rubber polymers that allow moisture transfer. | Drainage systems, agriculture, and environmental applications. | Integration with smart sensors for real-time monitoring. |

| Permeability | High permeability allowing for efficient water flow while retaining soil. | Landscaping, park planning, and urban water management. | Improved materials for enhanced durability and performance. |

| Size Options | Available in various diameters to suit specific needs. | Best suited for both small scale projects and large infrastructures. | Development of adjustable diameter designs. |

| Installation | Easy and quick installation process reducing labor costs. | Used in underdrains, foundation drainage, and solid waste management. | Automated installation techniques using robotics. |

| Environmental Impact | Designed to minimize environmental disruption during use. | Soil erosion control, water quality improvement, and sustainable design. | Biodegradable options being researched for eco-friendly applications. |