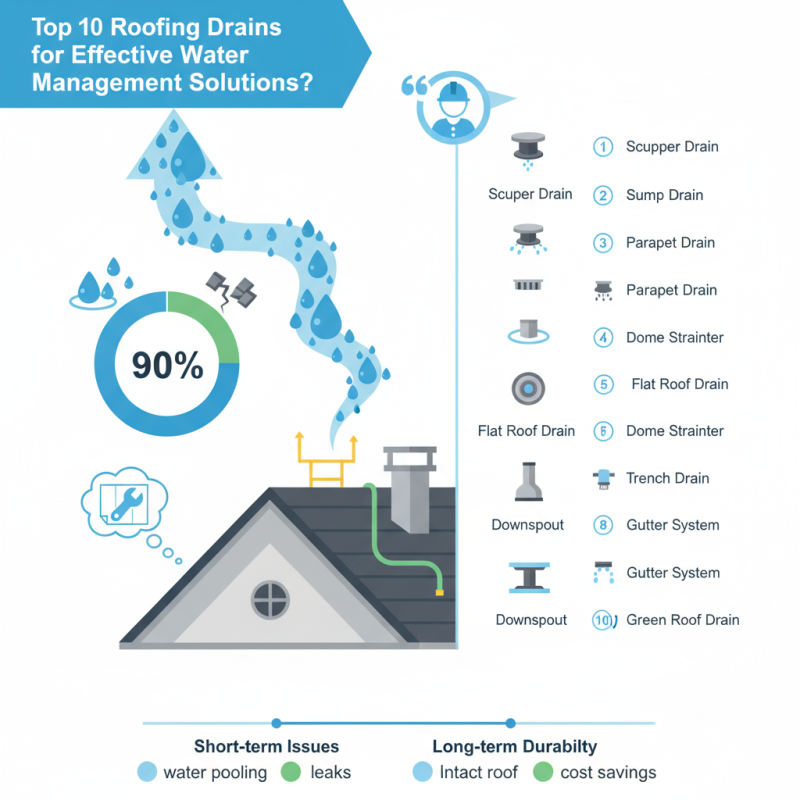

Effective water management is critical in roofing systems. Poor drainage can lead to significant issues, including water pooling and structural damage. The implementation of high-quality roofing drains is essential to ensure water efficiently exits the roof. According to a report by the National Roofing Contractors Association, almost 90% of roof failures are linked to inadequate drainage systems.

John Smith, a renowned expert in roofing solutions, emphasizes, "Proper roofing drains are vital for preserving a building's integrity." His insights highlight the importance of selecting the right drains for specific roofing applications. The right choice can prevent costly repairs and extend the roof's lifespan.

The market offers various options for roofing drains. However, many property owners overlook the significance of this infrastructure. Choosing the wrong type can result in inefficiencies. Thoughtful consideration of roofing drains is necessary. It's not just about functionality; it's about ensuring the long-term durability of the entire roofing system.

When it comes to roofing drains, design matters. Different types provide unique solutions for effective water management.

Traditional scupper drains are common on flat roofs. These drains allow water to flow off easily.

However, they can clog if debris accumulates. Regular maintenance is essential to prevent blockages.

Another option is internal roof drains. These are often installed in low-slope roofs. They are connected to piping systems to direct water away.

Although effective, they can increase installation complexity. Proper placement is crucial to ensure optimal drainage.

Consider a few tips for effective usage.

When choosing roofing drains, consider several critical factors. The location of your building impacts drainage needs. For example, urban areas face more runoff than rural settings. The design of your roof is also crucial. Flat roofs typically require different drainage solutions than sloped roofs.

Material is essential for durability. Stainless steel, for instance, is resistant to corrosion. However, it can be more expensive. Weight is another factor. Heavy drains may not be suitable for all roofs. Always assess the load-bearing capacity.

Tip:

Ensure proper spacing between drains. This helps manage water flow effectively. Too few drains can lead to ponding.

Don't overlook maintenance. Some materials will require more attention over time. A more durable option may reduce long-term costs. You might find that initial expense pays off later.

Tip:

Choose drains designed for easy accessibility. This simplifies maintenance checks and repairs. Simplifying access encourages regular inspections, ultimately extending your roof's life.

Effective roofing drain systems are critical for managing water on flat roofs. A report by the National Roofing Contractors Association (NRCA) indicates that improper drainage can lead to extensive damage, costing property owners thousands in repairs. Despite this, many buildings still lack adequate drainage solutions. Installing roof drains correctly can prevent pooling, which reduces the risk of leaks.

Best practices in installation include proper sizing of the drains. A common mistake is underestimating the volume of water that can accumulate. The American Society of Civil Engineers (ASCE) suggests that one square foot of drain should accommodate 2.5 gallons of water per minute during a heavy rain. Additionally, the slope of the roofing material should direct water efficiently toward drains. A slope of at least 1% is often recommended, yet many roofs fall short of this standard.

Choosing the right materials is equally important. While many opt for less expensive options, using high-quality materials can enhance durability and reduce maintenance. On some roofs, low-grade materials deteriorate quickly, leading to more frequent repairs. Often, property owners overlook these issues until it’s too late. Regular inspections can help identify problem areas, but they are frequently neglected. Without proactive measures, the systems may fail to perform as intended.

| Drain Type | Material | Flow Rate (GPM) | Installation Method | Best Use Case |

|---|---|---|---|---|

| Standard Roof Drain | Cast Iron | 30 | Top-Down | Flat Roofs |

| Adjustable Roof Drain | PVC | 25 | Adjustable Height | Variable Roof Heights |

| Siphonic Roof Drain | Aluminum | 40 | Siphon | Large Roof Areas |

| Scupper Drain | Stainless Steel | 35 | Side Wall | Edge of Roof |

| Parapet Drain | Copper | 20 | Integrated | Low Sloped Roofs |

| Hopper Drain | Fiberglass | 15 | Bottom-Up | Small Roof Sections |

| Floor Drain | Polypropylene | 10 | Surface Mount | Indoor Water Management |

| Grate Drain | Iron | 12 | Open Grate | Landscaped Areas |

| Deck Drain | Synthetic | 18 | Channel | Balconies and Patios |

| Roof Coaming Drain | Concrete | 50 | Embedded | Heavy Rain Areas |

Effective maintenance of roofing drains is crucial for long-lasting performance. Regular inspection is a must. Check for debris buildup, which can block water flow. This includes leaves, dirt, and even small objects. If left unaddressed, a blockage can lead to water pooling on the roof. Standing water increases the risk of leaks and structural damage.

Cleaning filters and grates regularly helps maintain good water management. Use a gentle approach. Harsh tools could damage the drain or surrounding roofing material. Running water through the system can help flush out minor clogs. Additionally, consider seasonal checks. The changing weather may affect your drainage system differently.

Record any issues you notice during inspections. Over time, these notes can reveal patterns. Perhaps one area requires more attention than others. Reflecting on your maintenance routine can lead to a more proactive approach, enhancing the system’s longevity. An effective roofing drain is a key player in protecting the building structure. Regular upkeep is not just a chore, but a necessary investment.

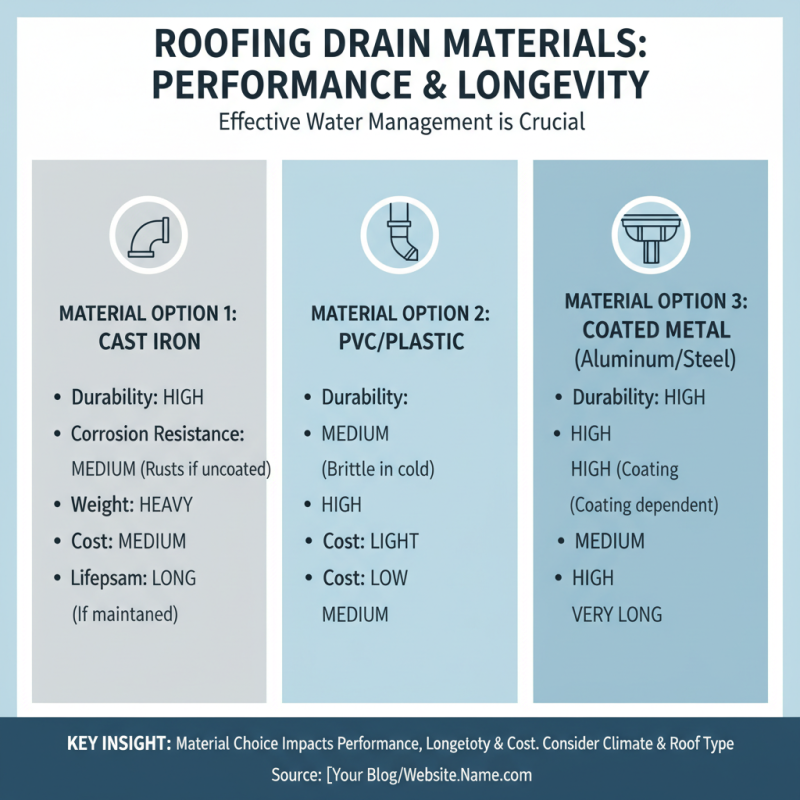

Effective water management is critical for any roofing system. The choice of materials for roofing drains directly impacts performance and longevity. A comparative analysis of material options reveals some interesting insights.

Metal drains, such as copper and aluminum, offer durability and corrosion resistance. These materials can withstand harsh weather conditions. Reports indicate that metal drains last approximately 20-30 years. However, they are prone to thermal expansion. This can cause potential leaks over time, especially as temperatures fluctuate. On the other hand, plastic drains are a popular alternative. They are lightweight and resistant to many chemicals. With a lifespan of 10-20 years, they may not last as long as metal options. Yet, they are often more affordable and easier to install.

Concrete drains have unique benefits, too. They are robust and can handle heavy loads. Yet, they can crack under extreme stress. Recent studies show that improper installation can significantly reduce their effectiveness. The challenge lies in balancing longevity, cost, and installation complexity. Finding the right material is essential for optimal water management solutions.